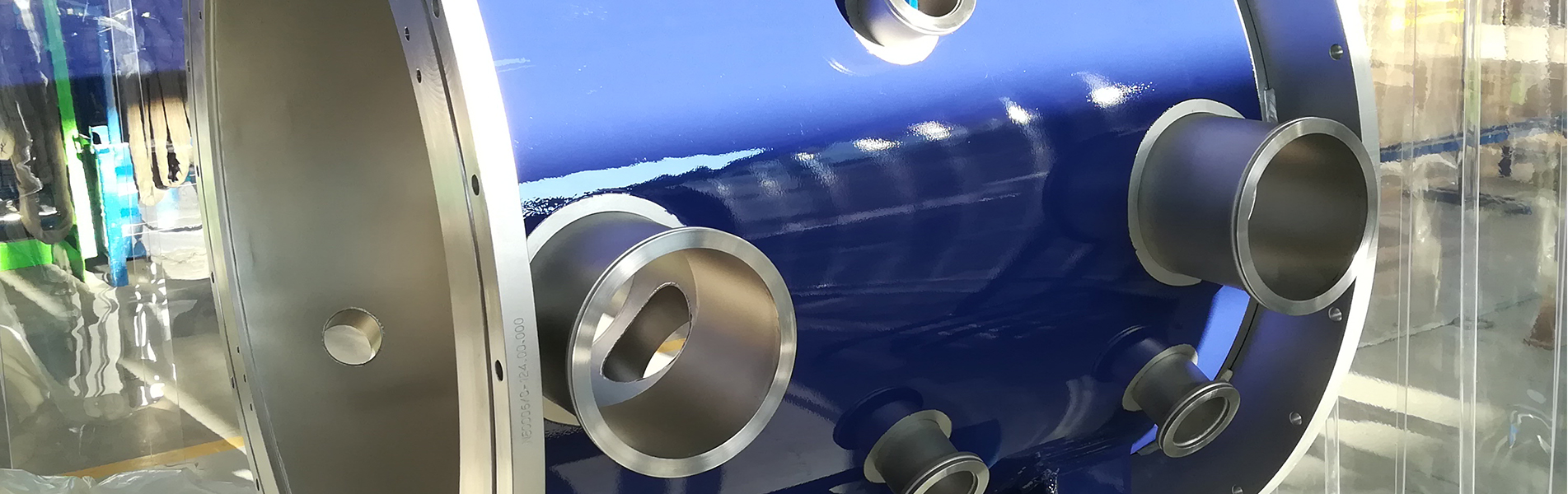

Configuration of individual vacuum chambers for various applications

Complex functional system TVAC (Thermal Vacuum Chamber) for research and aerospace industry – consisting of vacuum chamber, temperature control unit and vacuum control system

Production of the central component of a 30 t VIM system (vacuum induction furnace) (over 1,700 locksmith and welder hours), relocation of the welded component from the steel construction hall of STREICHER mechanical engineering to the boring mill hall approx. 500 m away

Then leak testing and surface coating in the steel construction hall, finally shipping to a Chinese special steel manufacturer

Details:

Length: 8.7 m long, width: 4.3 m, height: 5.75 m